Advanced Base Grooving Machine

- Robust Design With Hardened Spindle

- PLC Control with 4.3″ HMI & Controller

- Programmable designs (Can store upto 200 Design programs)

- Easy to operate

- Minimum changeover time

- Power failure Vacuum safety

- High Consistency in operation

Base Grooving Machine

- Hydraulic Operation

- User friendly design

- Two Speed Operation

- Easy to operate

- Programmable Timer controlled

- Production upto 2000 nos/shift*

- Contact for more details

Hydro pneumatic Press

- Press Capacity 2 ton to 40 ton

- Auto Ejection

- Higher Safety

- User friendly controller

- Operations : Punching, Stamping, Riveting, Forming, Flattening

- High Speed with low power consumption

- Production upto 5000 strokes/shift*

Semi Automatic Spray Painting Machine

- Save Paint and Labor

- Uniform Coating*

- Low Cost Solution

- User Friendly operation

- Best suited for induction based cookware

- Production upto 2000/Shift*

Vacuum Charakh Machine

(Horizontal / Vertical)

- Compact Construction

- Ergonomic Design

- Power failure safety for vacuum system

- Robust Design with Hardened Spindle

- Customization on request

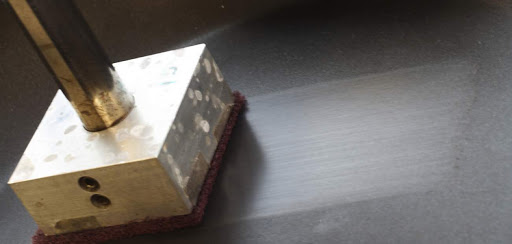

Abrasion Testing machine

- Variable Speed

- Variable stroke for variety of test area

- Multiple weights as per different test standards

- Pause play arrangement for inspection with buzzer

- Large table size for upto 320mm diameter vessles