1).Base Grooving Machine (Hydraulic)

- Performs Grooving/Design on rear side of cookware products.

- Hydraulic operation

- Dual speed operation. Slow & Rapid

- Manual setup and auto operation

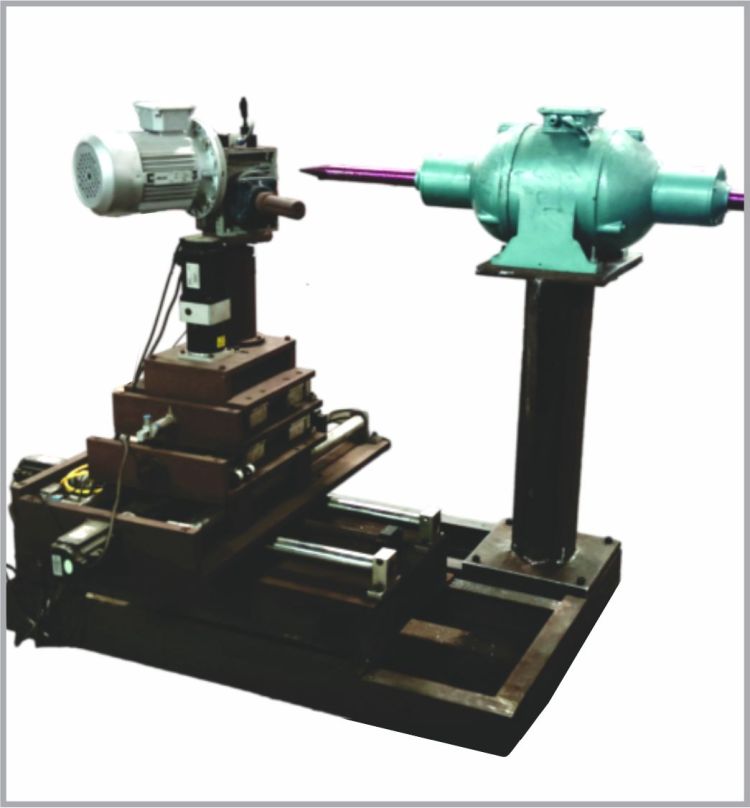

2).Servo Base Grooving Machine (Horizontal)

- Performs Grooving/Design on rear side of cookware products.

- Servo based operation.

- High accuracy and precision.

- Multiple speed and design variation possible.

- Can store multiple product Recipe/program.

3).CNC Base Grooving and Edge Trimming

- Performs Grooving/Design on rear side of cookware products.

- Servo based operation.

- High accuracy and precision.

- Multiple speed and design variation possible.

- Integrated Edge trimming function with the machine.

- Can store multiple product Recipe/program.

4).Servo Base Grooving Machine (Vertical)

- Performs Grooving/Design on rear side of cookware products.

- Servo based operation.

- High accuracy and precision.

- Multiple speed and design variation possible.

- Can store multiple product Recipe/program.

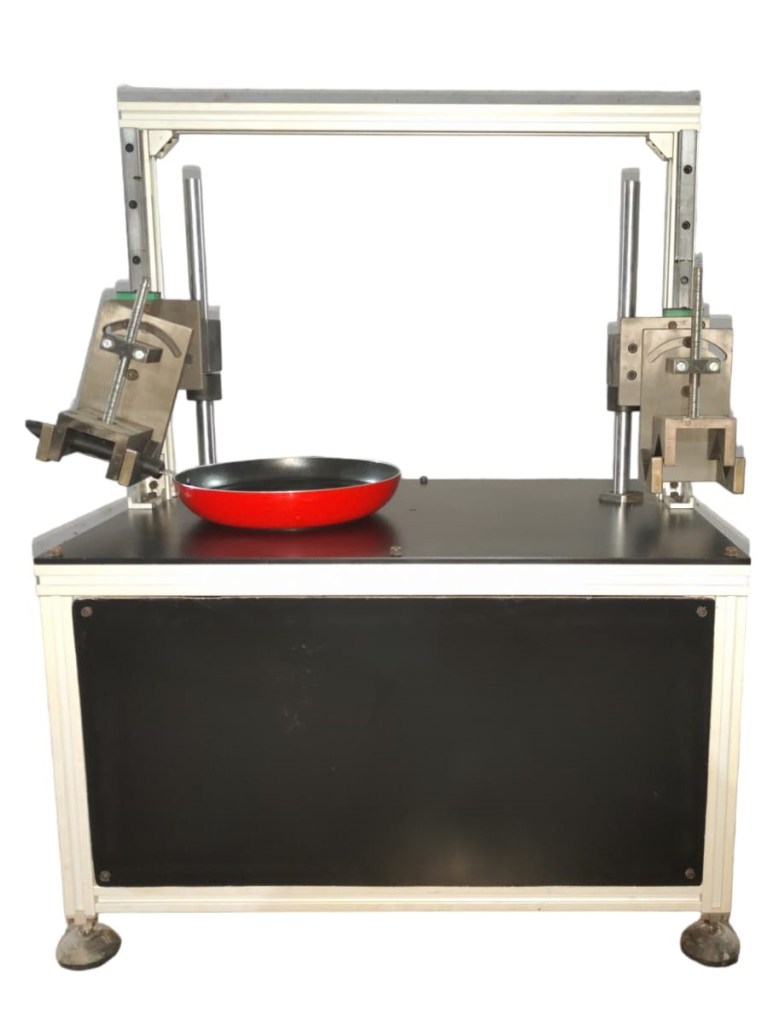

5).Automatic PTFE coating machine

- Machine designed for PTFE Coating process

- It can perform two layered wet on wet coating

- Improved quality and consistency

- Motion controller based operation.

- Can set products with different shapes and profiles

- Can store multiple product Recipe/program

6).Semi-automatic PTFE coating machine

- Small low coast automation product

- Enables to cover/mask induction plate on products at time of Exterior Coating

- Settable speed and timing

- Reduces painter fatigue to rotate base while painting.

- Can also be used only as rotation tool.

7).Hydropneumatic Flattening machine

- Flattening of base for Coated products post heating cycle.

- Can have different tonnage configurations between 4T to 15T.

- Hydropneumatics Operation.

- Clean system with multiple safety options.

8). Scrap baler machine

- Space saving solution for cutting scrap.

- Can compress scrap up to 80% of its volume.

- 20T of pressing action

- Hydraulic operation with ejection

- Manual operation or auto system also available

9). vacuum polishing machine

- Machine capable to hold product using vacuum

- Standard machine comes with 3HP motor

- Strong vacuum motor to hold heavy products

- It has different configuration options as shown above

Horizontal vacuum polishing machine

Vertical vacuum polishing machine

Inclined vacuum polishing machine

10) Cooker lid trimming machine

- Machine developed to trim edges of Inner lid cooker.

- Lid with ellipse shape has a special spindle developed for trimming purpose.

- Servo based operation for accurate results.

- Double station setup for increased production.

- Two independent stations with individual controllers.

11) Hydro-pneumatic riveting machine for Aluminium Rivets

- Compact low-cost riveting solution.

- Combined the speed of pneumatics and tonnage of hydraulics.

- Specially developed for cookware industry.

- High speed output & great results.

- Clean system as no hydraulics involved

Hydraulic Riveting for For Aluminim Rivets

Hydraulic Riveting machine for SS Rivets

13) Double side hole punching machine

- Enable to make holes on either sides of products as shown in video.

- Accurate holes exactly opposite

- Reduces error in Hole Punching operation when done manually.

- Suitable for variety of products.

14) Pneumatic buffing machine

- Simple buffing machine developed for finishing of flat walled or flat base products.

- Low-cost solution.

- Reduces dependability on skilled labour

- Consistent finish and output.

15) CNC buffing machine

- Motion controller based buffing machine

- Uses a 3 axis motion controller to control the system.

- Can store multiple product recipe.

- Suitable for multiple type of products.

16) Servo edge trimming machine

- Servo Machine developed to trim edges of cookware products.

- Servo system operated by controller.

- Accurate speed and dimension controls as it is servo system.

- Reduce dependability on skilled operator on conventional trimming machines

- High output, less maintenance.

17) Hydraulic Edge trimming machine

- Machine developed to trim edges of cookware products.

- Hydraulic system operated by controller.

- Sensor based setting of depth for cutting.

- Speed set by hydraulic system.

- Reduce dependability on skilled operator on conventional trimming machines

18) Abrasion testing machine Pneumatic

- Enable to make holes on either sides of products as shown in video.

- Accurate holes exactly opposite

- Reduces error in Hole Punching operation when done manually.

- Suitable for variety of products.

19) Abrasion testing machine Electric

- Capacity up to 6 kgf

- Variable Speed Setting

- Stops automatically after completing batch count

- Variable stroke adjustment as per requirement

- Can also provide machine with heater for extensive testing.

20) Handle testing machine

- Capacity up to 6 kgf

- Compatible for fatigue test as under IS 13395 : 2021

- Suitable for products with Single handle and Multiple handles

- Products like Tawa, Kadai, Fry Pan, Pots etc can be tested using this machine

21) Packing Conveyor

- We do conveyors for different applications like for material handling, packing etc

- It can be made as per required sizes and dimensions.