Whether you are assembling a large production line, installing automation equipment, building the machine structure, T- slotted aluminium extrusion is a good option. Many choose traditional welded steel structures to enhance their strength and durability. However, aluminium extrusion frames are becoming increasingly popular for several reasons.

Aluminium extrusion framework is a modular solution that consists of Aluminium extrusion profile with a unique T slot design and series of specialized connectors and fasteners, which allows designer or purchaser to adjust the structure frame according their own needs. Because the framework is aluminium, it often has a higher price tag than steel. But it offers distinct advantages as below.

Extensive Application Range:

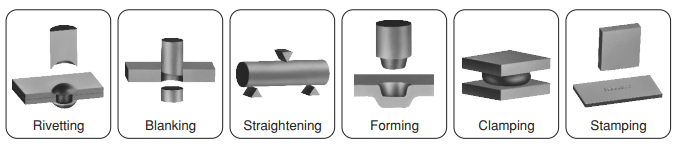

With its unique decoration, good sound insulation, heat preservation and recyclability are widely used in construction field, and with extrusion molding and high mechanical and physical properties, good thermal conductivity and high specific strngt. Suitable for machine frame, bracket door, industrial automation equipment, factory and office workbenches, shelves, containers, ladders, conveyor systems etc.

Easy of assembly and convenient installations:

Modular and multifunctional, without complex design and processing, can quickly frame an ideal mechanical equipment cover. Steel is a cheaper than aluminium in the same unit. But one implicit cost should not be ignored-labour, especially for intensive setup. During the assembly process, u need to hire professional assembler to put the pieces into place and even you have to employ skilled worker to cut, weld the material. And more is impossible to finish in a short time.

Adaptability to changes

The modular structure determines the T slot Aliminium extrusion framework own incomparable performance f adaptive variability, the frame system are much more flexible than steel. Pieces or parts can be interrupted and disconnected, then reassembled as needed. Moreover, the aluminium extrusion frame structure can be vernier adjustment, its simple to move the connectors or fasteners a few millimetres here or there to achieve proper installation. On the contrary, the steel must be planned a welded structure before installation, even each measurement and bolt must be precisely determined ahead of time. The moment these steels are permanently welded together and drilled into precise holes, it is hard to change the positions, so once the equipment and processes change down the road, the steel structure may not be able to adapt accordingly.

Attractive Appearance:

T slot aluminium extrusion frame needs not panting compared with steel structure which must be protectively coated to help slow he inevitable process. Anodized aluminium extrusion has the good looking appearance and good capacity of anti-corrosion by nature.

Easy maintenance:

Because of the modular nature of T slot aluminium extrusion frame, it’s easy and rapid to renewal the parts when the structure is damaged during production. But if you switch to another material, take steel structure for example, first you must stop production to repair it. You can imagine the process of maintenance: Cutting down the damaged pieces and welding back a new hole; the machine must stop working throughout the maintenance.