Hydropneumatic presses are initially driven by compressed air only, and then they activate the hydraulic power stroke automatically. These presses combine the benefits of pneumatic systems and hydraulic presses, taking the pneumatically driven fast stroke, which approaches the workpiece with low force, and combining it with the automatically-activated hydraulic power stroke that engages when it encounters resistance. As a result of this combination, the applied energy is used to the most economic effect. Hydropneumatic presses do not need a hydraulic power pack, and they can also be used where space is at a premium.

There are many benefits of using hydropneumatic presses, including:

- These presses use compressed air as their primary source of power, and it results in the inexpensive and reliable implementation of piping systems and components. This completely eliminates the need for expensive hydraulic components such as hydraulic oil.

- Force and Speed of the cylinder can be infinitely adjusted.

- Rapid, pneumatically operated approach stroke and return stroke. The design of the cylinder is such that return force is larger than the approach force, resulting in the loading of heavier tools for respective tonnages.

- Absolute separation of air and oil chambers. This has been achieved by providing bleed holes between the pneumatic and hydraulic seals. In the event of failure of pneumatic seals, the air escapes to atmosphere through a bleed hole and does not mix with the hydraulic oil. If the hydraulic seals fail, oil escapes from its bleed hole, indicating deterioration of the seal, which can be procured and replaced well before total breakdown occurs.

- Hydropneumatic presses are lightweight and compact, which makes it easy to mount them on a table. Additionally, there is no need to install a hydraulic power pack, which can save you a lot of floor space.

- These presses are serious energy savers. They can save up to 50% in energy inputs over fully hydraulic and pneumatic systems, and they can save more than 70% in terms of cost compared to traditional hydraulic systems.

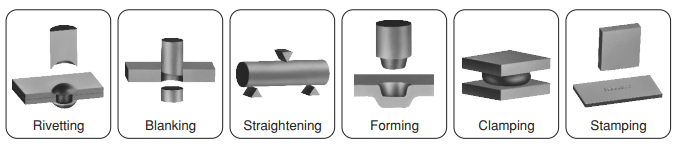

Hydro-pneumatic presses are used over pneumatic and hydraulic presses for a variety of applications, like bending, riveting, forming, marking, clamping, punching, and straightening. And that’s because of their above mentioned advantages.